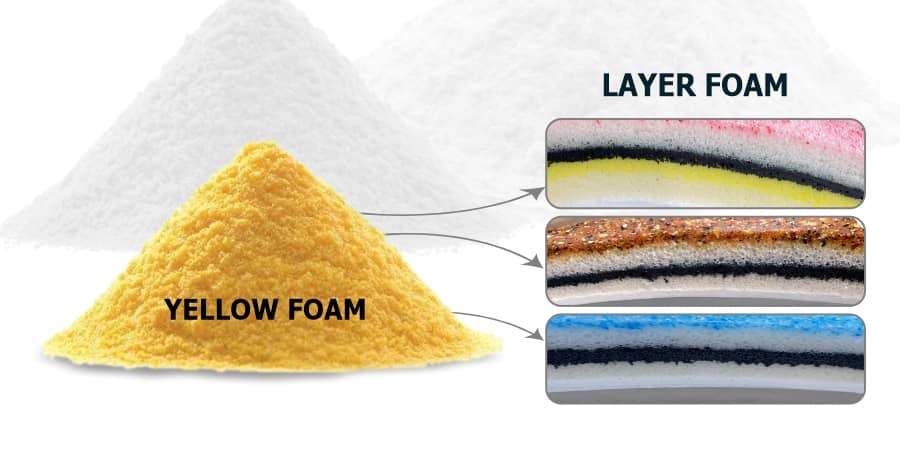

Roto Foam & LLDPE Foam Material Manufacturer

LLDPE foam is a closed cell foam, also referred to as a PE foam or Polyethylene. The Foam material starts off as a thermoplastic which is then blown into a foam format. This is a highly durable as well as versatile product. We are manufacturer and Supplier of Roto Foam and Foam Materials. This foam materials is a formulated material Linear Low-Density Polyethylene, with a foaming agent suitable for rotational moulding.

Specification

- LLDPE based foam compound formulated with a blend of chemical blowing.

- Carrier resin:LLDPE.

- Yellowish polymeric pulverised powder.

- Expansion: 4x than normal PE layer (4mm to 15mm).

- Moulded density: 0.230.

- Suggested quantity: 100% weight of foam layer (ready to use).

- Processing temp: 190 - 205°C.

- Our latest experimental results indicate that heating time and the processing temperature plays important roles in determining fine cell structure in rotational foam moulding.

- Insulation: Excellent insulation properties.

- Close cell structure: It provides better strength.

- Light weight: Higher stiffness at lower cost.

- Joint layers: Strong bonding between layers.

- Easy process: Use existing machines. Box type rock & roll, 4 arm bi-axel machine,open fire machine, 3-4 single arm, shuttle type machine.

- Packaging: 25 kg (1 Beg).

- 0% rejection in our foam (easy to operate).

- We already use 30 ton/month in our unit.

- PE foam material increases the strength of moulded parts rather than normal PE layer.

- 100% recyclable.

Quick Contact