LLDPE Plastic Water Tank Raw Material Manufacturer

We are leading manufacturer of LLDPE Raw Material including Plastic Raw Material and Water Tank Raw Material. These LLDPE Plastic raw material are something that you use in your everyday life, all the time, from the first thing in the morning when you open the fridge to the last thing when you brush your teeth in the evening. Plastic is everywhere and it is an easy material to work with. It has many applications and is available in countless variations. Water Tank Raw Material are manufactured for making best quality water tanks.

What are plastic raw materials?

What we call plastic is actually a variation of chemical compounds that are built in long chains. These are called polymers and are in turn constructed of smaller pieces called monomers. The polymers we call plastics are used for example in water tank. It is a plastic raw material that has been modified in different ways, either it has been dyed with pigments, reinforced with glass fiber or modified with plasticizers to give the plastic raw material different properties.

Specification

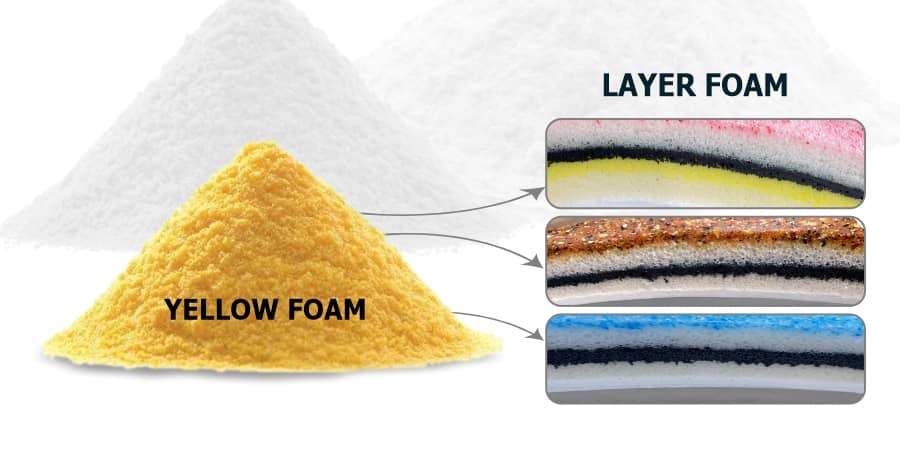

- LLDPE based foam compound formulated with a blend of chemical blowing.

- Carrier resin:LLDPE.

- Yellowish polymeric pulverised powder.

- Expansion: 4x than normal PE layer (4mm to 15mm).

- Moulded density: 0.230.

- Suggested quantity: 100% weight of foam layer (ready to use).

- Processing temp: 190 - 205°C.

- Our latest experimental results indicate that heating time and the processing temperature plays important roles in determining fine cell structure in rotational foam moulding.

- Insulation: Excellent insulation properties.

- Close cell structure: It provides better strength.

- Light weight: Higher stiffness at lower cost.

- Joint layers: Strong bonding between layers.

- Easy process: Use existing machines. Box type rock & roll, 4 arm bi-axel machine, 3 arm bi-axel machine, open fire machine, 3-4 single arm, shuttle type machine.

- Packaging: 25 kg (1 Beg).

- 0% rejection in our foam (easy to operate).

- We already use 30 ton/month in our unit.

- PE foam material increases the strength of moulded parts rather than normal PE layer.

- 100% recyclable.

Quick Contact